In gas welding the heat to melt the metal parts being welded is produced by the combination of oxygen and an inflammable gas such as acetylene, propane, butane, etc. Acetylene is the most commonly used gas; propane and butane are cheaper but less efficient.

In gas welding the heat to melt the metal parts being welded is produced by the combination of oxygen and an inflammable gas such as acetylene, propane, butane, etc. Acetylene is the most commonly used gas; propane and butane are cheaper but less efficient.

Oxyacetylene welding

A flame temperature of about 3250 "C melts the metals which fuse together to form a strong joint. Extra metal may be supplied from a filler rod and a flux may be used to prevent oxidation. The gas is supplied from high pressure bottles fitted with special regulators which reduce the pressure to 0.134.5 bar. Gauges indicate the pressures before and after the regulators. A torch mixes the gases which issue from a copper nozzle designed to suit the weld size. The process produces harmful radiation and goggles must be worn. The process is suitable for steel plate up to 25mm thick, but is mostly used for plate about 2 mm thick.

Labels: welding

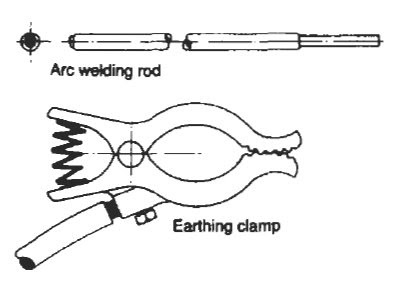

The heat of fusion is generated by an electric arc struck between two electrodes, one of which is the workpiece and the other a ‘welding rod’. The welding rod is made of a metal similar to the workpiece and is coated with a solid flux which melts and prevents oxidation of the weld. The rod is used to fill the welded joint. Power is obtained from an a.c. or d.c. ‘welding set’ providing a regulated low-voltage high-current supply to an ‘electrode holder’ and ‘earthing clamp’. The work is done on a steel ‘welding table’ to which the work is clamped and to which the earthing clamp is attached to complete the circuit.

Labels: welding